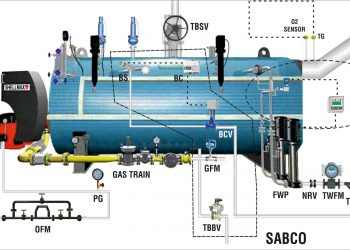

The model 61 automatic boiler blowdown control system from ecd provides a reliable solution for the continuous control of the surface blowdown rate for commercial and industrial boilers.

Automatic boiler blowdown control system.

In the case of remedial work once the pressure has been relieved the downstream isolation valve will be closed.

The bdvs require a downstream isolation valve with a bleed between the two.

The model 61 boiler blowdown control system is a rack mount plug and play system which is easy to set up simple to operate and provides cost savings over.

An automatic blowdown control system optimizes surface blowdown rates by regulating the volume of water discharged from the boiler in relation to the concentration of dissolved solids present.

Automatic surface blowdown control systems maintain water chemistry within acceptable limits while minimizing blowdown and reducing energy losses.

Blowdown valves bdvs are used to depressurize a system or component in order to carry out maintenance work or if there is an emergency.

Ian sutton in plant design and operations 2015.

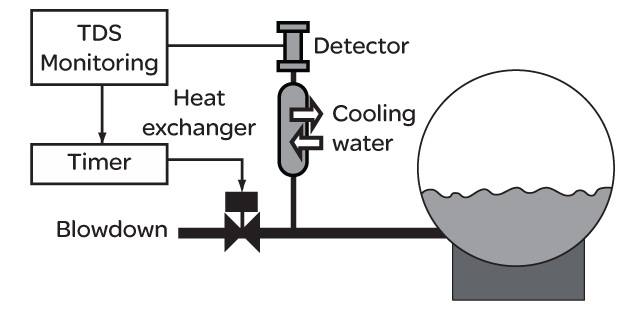

An automatic blowdown control system continuously monitors the boiler water adjusts the rate of blowdown and maintains the specific conductance of the boiler water at the desired level.

The basic components of an automatic blowdown control system include a measurement assembly a control center and a modulating blowdown control valve.

An automatic blowdown control system optimizes surface blowdown rates by regulating the volume of water discharged from the boiler in relation to the concentration of dissolved solids present.

An electronic unit and timer controls the ball valve and boiler.

An automatic blowdown system may be installed on any steam boiler regardless of size or operating duty cycle.